상세 컨텐츠

본문

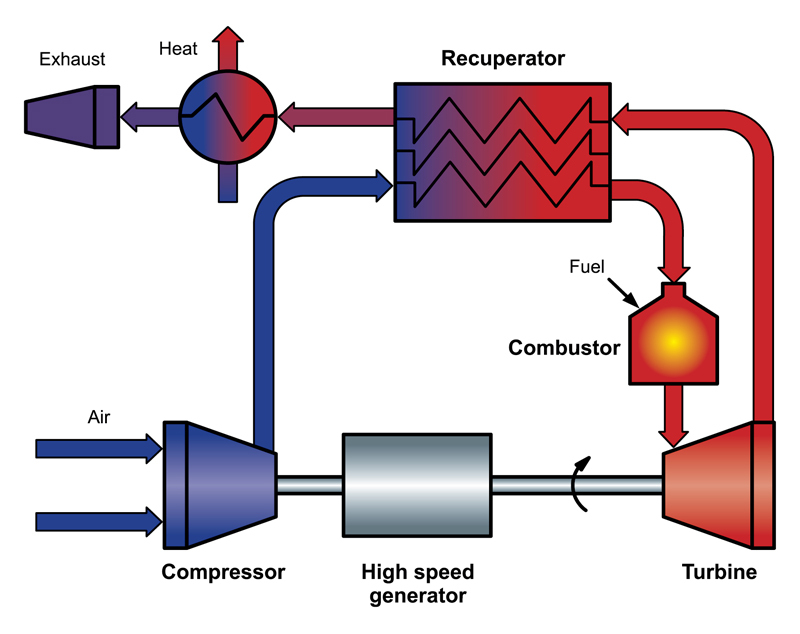

II. Components of a Micro Gas Turbine Engine

- Compressor

The compressor is a key component of a micro gas turbine engine, and it plays a crucial role in the power generation process.

The compressor's main function is to compress the air and fuel mixture before it enters the combustion chamber. Compression increases the pressure and temperature of the air and fuel mixture, which improves the combustion process and increases the power output of the engine.

There are several types of compressors used in micro gas turbine engines, including axial compressors, radial compressors, and centrifugal compressors.

- Axial compressors: Consist of a series of rotating blades, called rotor blades, and stationary blades, called stator blades. The rotor blades rotate and compress the air as it passes through, while the stator blades guide the air and maintain its flow.

- Radial compressors: Consist of a series of vanes that rotate around a central shaft. The vanes compress the air as it flows radially outward from the center of the compressor.

- Centrifugal compressors: Consist of a impeller that spins at high speeds and compress air by centrifugal force, and a diffuser that converts the kinetic energy of the compressed air into pressure energy.

In summary, the compressor is a critical component of a micro gas turbine engine that compresses the air and fuel mixture before it enters the combustion chamber, this improves the combustion process and increases the power output of the engine.

Combustion chamber

The combustion chamber is a key component of a micro gas turbine engine.

It is where the compressed air and fuel mixture is ignited and burned to generate power.

The combustion chamber typically consists of two main parts: a liner and a combustor.

The liner is a hollow chamber that surrounds the combustor and is designed to withstand the high temperatures and pressure generated during combustion.

The combustor is a device that controls the combustion process, and it typically consists of a series of nozzles, called injectors, that deliver the fuel into the combustion chamber, and a series of air channels, called swirler, that mix the fuel with the compressed air.

There are several types of combustors used in micro gas turbine engines, including:

- Can-annular combustor: A cylindrical combustor with a central fuel injector surrounded by an annular air swirler.

- Annular combustor: A combustor that surrounds the turbine and nozzle guide vanes.

- Reverse flow combustor: A combustor that uses a reverse flow of air to mix the fuel and air.

The combustion process in micro gas turbine engines typically uses a lean premixed combustion, in which a lean mixture of air and fuel is ignited and burned in the combustion chamber. This results in lower emissions and higher thermal efficiency than other combustion methods.

In summary, The combustion chamber is a crucial component of a micro gas turbine engine, where the compressed air and fuel mixture is ignited and burned to generate power. It typically consists of a liner and a combustor, which controls the combustion process, and it can be of different types depending on the design of the engine.

Turbine

A turbine is a key component of a micro gas turbine engine that converts the thermal energy from combustion into mechanical energy to drive the compressor and the generator.

The turbine consists of a series of blades, called rotor blades, that rotate at high speeds. The hot gases from the combustion chamber enter the turbine and expand through the rotor blades, which causes the rotor blades to rotate. The turbine is connected to the compressor and the generator by a shaft, which allows the mechanical energy generated by the turbine to be transferred to the compressor and the generator.

There are two main types of turbines used in micro gas turbine engines: the axial turbine and the radial turbine.

- Axial turbine: Consist of a series of rotor blades and stator blades that are arranged in a linear, or axial, configuration. The hot gases expand through the rotor blades and stator blades, which causes the rotor blades to rotate.

- Radial turbine: Consist of a series of rotor blades that are arranged in a radial configuration around a central shaft. The hot gases expand through the rotor blades, which causes the rotor blades to rotate.

The turbine plays a crucial role in the power generation process of a micro gas turbine engine by converting the thermal energy from combustion into mechanical energy. The turbine's design, the number of blades, the materials and the coating used in the blades, and the cooling system used are all critical factors that impact the turbine's performance, efficiency, and lifespan.

In summary, The turbine is a key component of a micro gas turbine engine that converts the thermal energy from combustion into mechanical energy to drive the compressor and the generator. The turbine consists of a series of blades, called rotor blades, that rotate at high speeds and hot gases from the combustion chamber expand through them. There are two main types of turbines used in micro gas turbine engines: the axial turbine and the radial turbine. The turbine's design, the number of blades, the materials and the coating used in the blades, and the cooling system used are all critical factors that impact the turbine's performance, efficiency, and lifespan.

Generator

A generator is a key component of a micro gas turbine engine that converts the mechanical energy from the turbine into electrical energy.

The generator typically consists of a rotor, which rotates at high speeds, and a stator, which is a stationary component that surrounds the rotor. The rotor is connected to the turbine by a shaft, which allows the mechanical energy from the turbine to be transferred to the rotor. The rotor is typically made of a magnet and the stator is typically made of coils of wire. When the rotor rotates, it generates a magnetic field that induces an electrical current in the stator coils. This process is known as electromagnetic induction.

There are two main types of generators used in micro gas turbine engines: the alternating current (AC) generator and the direct current (DC) generator.

- Alternating current (AC) generator: Generates an alternating current that can be easily transmitted over long distances and easily converted to different voltages.

- Direct current (DC) generator: Generates a direct current that is not easily transmitted over long distances and not easily converted to different voltages.

The generator plays a crucial role in the power generation process of a micro gas turbine engine by converting the mechanical energy from the turbine into electrical energy. The generator's design, the materials used in the rotor and stator, and the cooling system used are all critical factors that impact the generator's performance, efficiency, and lifespan.

In summary, A generator is a key component of a micro gas turbine engine that converts the mechanical energy from the turbine into electrical energy. It typically consists of a rotor, which rotates at high speeds, and a stator, which is a stationary component that surrounds the rotor. There are two main types of generators used in micro gas turbine engines: the alternating current (AC) generator and the direct current (DC) generator. The generator plays a crucial role in the power generation process of a micro gas turbine engine by converting the mechanical energy from the turbine into electrical energy. The generator's design, the materials used in the rotor and stator, and the cooling system used are all critical factors that impact the generator's performance, efficiency, and lifespan.

Other auxiliaries and control systems

In addition to the compressor, combustion chamber, turbine, and generator, a micro gas turbine engine also typically includes a number of other auxiliaries and control systems that help to support and control the operation of the engine. Some of these include:

- Fuel system: Provides fuel to the combustion chamber for combustion. This typically includes a fuel pump, fuel filter, and fuel control valve.

- Lubrication system: Lubricates the moving parts of the engine to reduce wear and tear. This typically includes an oil pump, oil filter, and oil cooler.

- Air intake system: Brings in fresh air to the compressor for compression. This typically includes an air filter and an air inlet valve.

- Exhaust system: Removes the hot gases from the turbine to the atmosphere. This typically includes an exhaust turbine and a muffler.

- Cooling system: Keeps the engine components cool during operation. This typically includes a radiator and a fan.

- Control system: Monitors and controls the operation of the engine. This typically includes sensors, actuators, and a control unit.

- Electrical system: Supplies power to the engine's control systems. This typically includes a battery and an alternator.

These auxiliaries and control systems work together to support and control the operation of the micro gas turbine engine, and their proper operation is crucial for the safe and efficient operation of the engine.

In summary, In addition to the compressor, combustion chamber, turbine, and generator, a micro gas turbine engine also typically includes a number of other auxiliaries and control systems that help to support and control the operation of the engine. Some of these include: Fuel system, Lubrication system, Air intake system, Exhaust system, Cooling system, Control system, and Electrical system. These auxiliaries and control systems work together to support and control the operation of the micro gas turbine engine, and their proper operation is crucial for the safe and efficient operation of the engine.

'MICRO GASTURBIBE ENGINE' 카테고리의 다른 글

| Micro Gas-turbine Engine(151) (0) | 2023.01.29 |

|---|---|

| Micro gas-turbine engine(150) (0) | 2023.01.29 |

| Micro gas-turbine Engine(149) (0) | 2023.01.29 |

| Micro Gas-Turbine Engine(147) (0) | 2023.01.29 |

| Micro Gas-turbine Engine (146) (0) | 2023.01.29 |